- 您所在的位置: 首页

业务范围

业务范围  模具设计

模具设计 - 模具设计

-

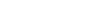

我们的工程师具有多年工作经验,熟识各种模具结构。熟练操作UG、PRO-E、SolidWorks、CAD等各种设计软件。客户的产品设计理念我们能精确地表达出来,更快将理念转化为产品。采用先进的CAD/CAM/CAE软件,对产品、模具进行分析,针对有可能出现的问题在设计前期做好预防,缩短了模具修整时间。合理的模具结构能延长模具寿命、提高生产效率,从而降低生产成本。

我们的工程师具有多年工作经验,熟识各种模具结构。熟练操作UG、PRO-E、SolidWorks、CAD等各种设计软件。客户的产品设计理念我们能精确地表达出来,更快将理念转化为产品。采用先进的CAD/CAM/CAE软件,对产品、模具进行分析,针对有可能出现的问题在设计前期做好预防,缩短了模具修整时间。合理的模具结构能延长模具寿命、提高生产效率,从而降低生产成本。

我们工厂分为工程部大模事业部、精密事业部、注塑部 四大部门。将模具分类可以方便管理,更有利发挥各自的特长,提高加工效率及品质。

CAD

Using Pro-Engineer, Unigrahics and AutoCAD for product design and mold design. Pro-Engineer and Unigrahics possess the capability of direct part line processing from product 3D model. The assembly drawing is generated from defining parameters for standard components of mold base, insert parts, slides. The design is completed in a 3D environment and the drawings can be generated in 2D format.

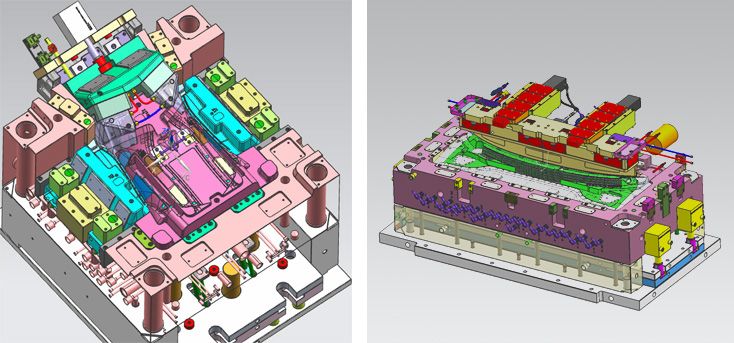

CAM

2-shots Moldflow Analysis

Our superior level of engineering expertise and CAM technology enables us to program even the most intricate cutter paths from surface geometry for molds that are production ready right from the very start. The Powermill software is extended into the CAM process. Data consistency is guaranteed by using the data from the CAD file for the CAM job of NC programming.

CAE

We use a variety of Mold flow analyses early in the project cycle. Plastics Advisor provides a quick assessment of a part‘s ability to be filled based on specific material grade and gate locations. Parts with fill issues or inconclusive data output may undergo more advanced analysis that takes into account additional variables for more comprehensive results. It will offer to mold designer the best reference solution and greatly reduce the tooling and moulding development lead time.